Product Information

What is powder coating?

Powder coating is a dry finishing process that involves applying a

fine, free-flowing powder to a surface, which is then cured under

heat to form a durable, protective, and decorative layer. Unlike

traditional liquid paint, powder coating does not require solvents,

making it an environmentally friendly option.

How It Works

- Application: The powder is applied electrostatically using a

spray gun, which charges the particles, causing them to adhere to

the grounded surface.

- Curing: The coated object is heated in a curing oven, where the

powder melts and forms a smooth, even film.

- Cooling: After curing, the surface cools and hardens into a

durable finish.

Key Features

✔ Color-Shifting Effect – Displays multiple hues (e.g.,

purple-to-green, blue-to-red, gold-to-violet) as the viewing angle

changes.

✔ Durable & Protective – Epoxy-polyester hybrid formulation ensures

excellent adhesion, corrosion resistance, and UV stability.

✔ Metallic Finish – Provides a high-gloss, reflective metallic

appearance for a premium look.

✔ Environmentally Friendly – Powder coating is solvent-free,

reducing VOC emissions.

✔ Heat & Chemical Resistant – Withstands high temperatures and resists abrasion, chemicals, and

weathering.

Common Applications

Automotive Parts (wheels, trim, accessories)

Motorcycles & Bicycles (frames, rims)

Consumer Electronics (laptops, phone cases)

Home & Industrial Decor (furniture, lighting, appliances)

Sporting Goods (golf clubs, helmets)

Benefits Over Liquid Paint

No drips or runs (powder adheres electrostatically)

Faster curing (energy-efficient process)

Thicker coatings in one application

Easier cleanup & reuse of overspray

Instruction

Application Voltage | 60-90 KV |

Gun to Component Distance | 15-30CM |

Curing Temperature | 180-200℃,10 min-15 min |

Storage Stability

♦Store in ventilated, dry, clean room, temperature < 25℃ | ♦Relative humidity 50-65% |

♦Away from direct sunlight, fire, heat | ♦For best performance, use within 6 months |

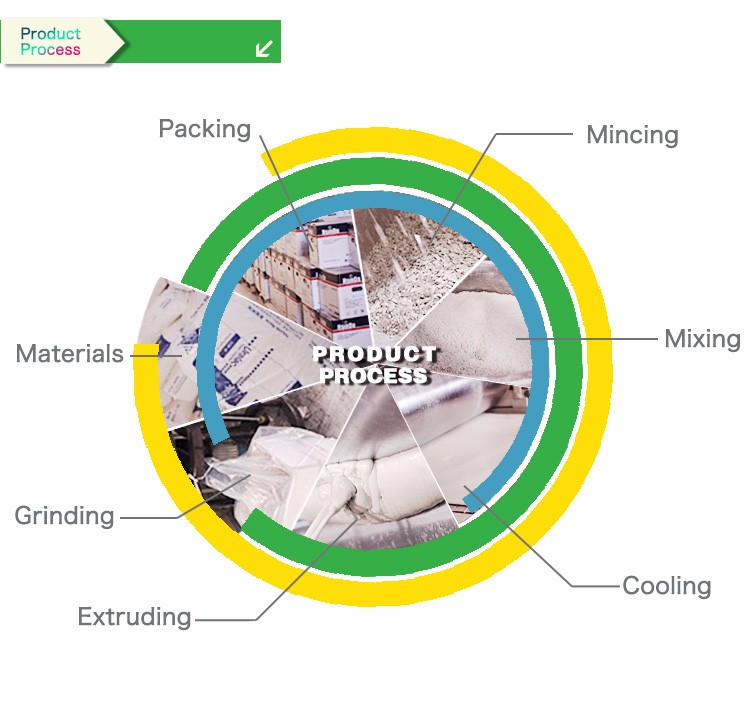

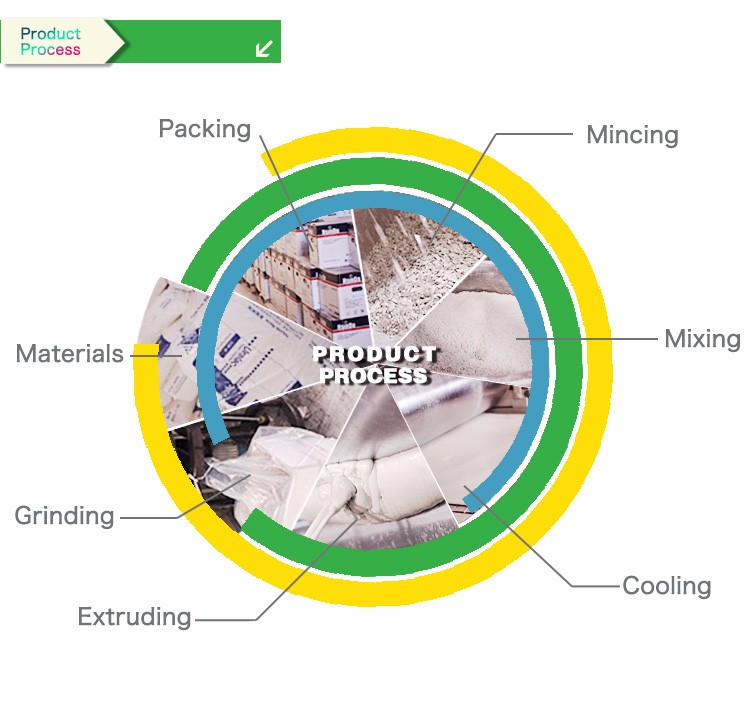

Product process

Product test

Quality control

Test Item | Test Method | Test Result |

Film Thickness | ISO2360 | 60-80um |

Pencil Hardness | ASTMD 3363 | HB-H |

Bending | ISO1519 | ≤10mm |

Grid Test 1mm | ISO2409 | 0 Class |

Impulse Test | ASTMD2794 | Pass |

Cupping Test | ISO1520 | ≥8mm |

Heat Resistance 1000 hours | ISO6270-1 | Popping<1mm |

Shigh gloss mirror chrome sliver spray paint powder coating Spray

1000 hours | ISO9227 | Corrosion Spreading<1mm |

Hsinda powder coating, offers the best levelling and adhesion to

metal surface, with above 60% DSM resin content.

Packing & Shipping

Trade Terms | FOB, CIF, CRF, CNF |

Payment Terms | T/T, L/C, West Union, PayPal etc. |

Delivery time | 3-7 days after payment |

Packaging | Size: 39*26*43 (unit:cm) Weight: N.W. 25kg G.W. 26kg |

Shipping | By sea, by air, by courier |

Certificates

Company Information

- Company Name: Chengdu Hsinda polymer material co.,ltd

- Business Type: Manufacturer, Trading Company

- Year established: 2011

- Company Certifications:Supplier Assessment Certificate; ISO9001;SGS

- Main products: Epoxy powder coating, Polyester powder coating,

Epoxy-polyester powder coating etc.

- Production Line: four advanced large-scale production lines, two

experiment production lines

- Yearly capacity: 5000 tons

- Export market: Domestic Market, Africa, South America, Western

Europe, Mid East etc.

- Advantage: Well- advanced manufacturing equipment, professional

testing facilities,and excellent research group.

Our Partners

Contact Us